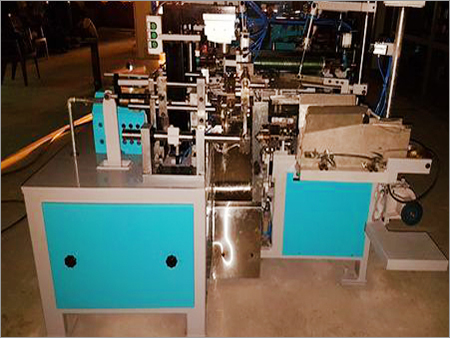

Semi Automatic Paper Core Making Machine

Semi Automatic Paper Core Making Machine Specification

- Grade

- Industrial Grade

- Type

- Semi Automatic Paper Core Making Machine

- Material

- Mild Steel

- Capacity

- 60-120 pieces/hour

- Computerized

- No

- Control System

- Semi-automatic control panel

- Cutting Speed

- Up to 25 m/min

- Cutting Size

- 300 mm to 3000 mm (length)

- Cutting Thickness

- 2 mm to 12 mm

- Voltage

- 220-440 V

- Power

- 4.5 kW

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 3500 x 1200 x 1500 mm

- Color

- Blue & White

Semi Automatic Paper Core Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 40 Days

About Semi Automatic Paper Core Making Machine

With the support of our diligent employees, we are known manufacturers and exporters of Semi Automatic Paper Core Making Machine. This machine is specifically designed to work for mass production of cores, spiral paper tubes and composite cans for packaging industries. It is also capable of delivering burr free cores without dust and noise generation. Thus, for delivering excellent quality machines, we utilize premium quality raw materials and new advanced technologies in the manufacturing process. Semi Automatic Paper Core Making Machine is thus highly demanded its low maintenance and easy to use the feature. Further, we test it over different quality parameters to ensure it reaches its destination without getting damaged.

Product details

|

Material |

MS |

|

Country of Origin |

Made in India |

|

Motor Power |

8 HP |

|

Voltage |

415 V |

|

Surface Finishing |

Color Coated |

|

Phase |

3 Phase |

|

Frequency |

50-60 Hz |

|

Power Source |

Electric |

|

Automation Grade |

Semi-Automatic |

|

Brand/Make |

Lottery Tech |

|

Capacity |

900 kg per hour |

Efficient Core Production

With a cutting speed of up to 25 meters per minute and the ability to produce 60-120 pieces per hour, this machine is designed for continuous, reliable output. Its motorized chain drive system and semi-automatic control panel ensure ease of operation and consistent quality, making it a valuable addition to any mid-to-large scale manufacturing line.

Versatile and Durable Design

Built with robust mild steel and finished with a powder-coated surface, the machine features alloy steel rollers with hard chrome plating for longevity. The equipment supports both spiral and parallel wound core production, and accommodates 2 mm to 12 mm cutting thickness for diverse industrial requirements.

Streamlined Operation and Safety

Employing an automatic ejection system and requiring just one operator, the machine is designed for smooth workflow and operator safety. Its noise level is kept below 70 dB, ensuring a comfortable working environment. The units semi-automatic panel makes it easy for operators to manage the process efficiently.

FAQs of Semi Automatic Paper Core Making Machine:

Q: How does the semi automatic paper core making machine function?

A: The machine utilizes a motorized chain drive system to wind multiple paper plies (up to 7 layers) around alloy steel rollers, forming spiral or parallel wound cores. It handles automatic or manual gluing and features automatic tube ejection to streamline the production process.Q: What are the available core sizes and cutting specifications?

A: This machine can produce cores with diameters ranging from 25 mm to 150 mm and cut lengths from 300 mm to 3000 mm. It supports core wall thicknesses of 2 mm to 12 mm and operates at cutting speeds of up to 25 meters per minute.Q: When should this machine be used in manufacturing?

A: Its most suitable for medium to high-volume production environments in industries such as textile, paper, film, and packaging, where consistent quality and efficiency in paper core production are required.Q: Where can this machine be installed and what are its space requirements?

A: Designed for industrial environments, the machine measures 3500 x 1200 x 1500 mm and weighs 1200 kg. It requires a stable floor space, a power connection of 220440V, and adequate ventilation for optimum operation.Q: What is the process for changing between spiral and parallel core production?

A: Switching between spiral and parallel wound production involves adjusting the settings on the semi-automatic control panel and, if necessary, reconfiguring the roller arrangement, allowing for flexibility to meet diverse production needs.Q: How does the automatic ejection system benefit the operator?

A: The automatic ejection system enables finished tubes to be efficiently removed from the machine, reducing manual labor, speeding up workflow, and allowing a single operator to manage the entire process safely and easily.Q: What are the main advantages of using this semi automatic paper core making machine?

A: Key benefits include high production capacity, versatility in core types and sizes, robust construction with powder coating, low noise operation, and a user-friendly semi-automatic control system, leading to improved efficiency and safety on the manufacturing floor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi Automatic Paper Core Machine Category

Paper Tube GLUE MIXTURE

Minimum Order Quantity : 1 Unit

Material : Mild Steel Body

Grade : Other, Industrial Grade

Control System : Other, Manual

Computerized : No

Spiral Paper Core Making Machine

Minimum Order Quantity : 1 Unit

Material : MS

Grade : Automatic

Control System : PLC Control

Computerized : No

Warranty : 1 Year

Fully Automatic Paper Core Making Machine

Minimum Order Quantity : 1 , Unit

Material : MS

Grade : Automatic

Control System : PLC Control

Computerized : No

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese